1878

IT HAPPENED IN…1878

Yellow fever swept thru the South and as far

north as Ohio, with an estimated 14,000 fatalities.

Cigars and whiskey were recommended by some as remedies.

The steamer

J. M.

White set a speed record traveling up the

Mississippi River from New Orleans to St. Louis in three days, 23

hours, 9 minutes.

Henry Putnam patented his external, swing-type

Lightning bottle stopper.

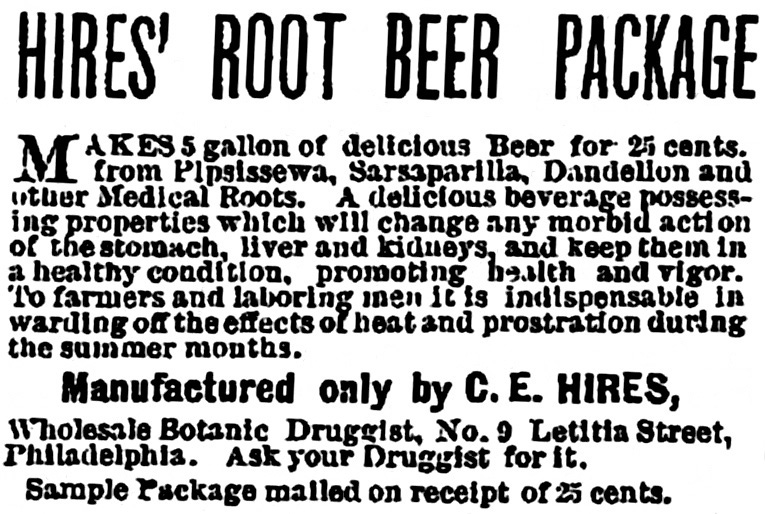

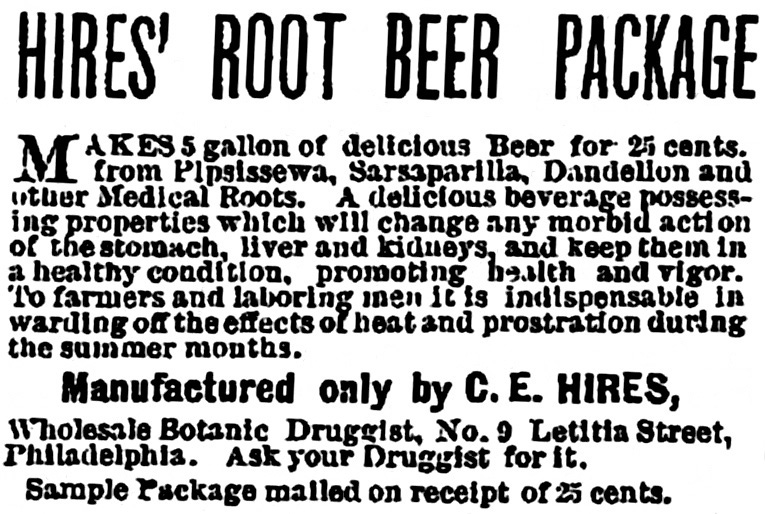

In

addition to the advertising copy used in 1877, a “Sample Package mailed

on receipt of 25 cents.” was added to this newspaper listing.

Offering samples via mail proved a highly successful way to

promote Hires’ Root Beer for home use and a major Hires marketing

initiative for decades.

(Figure

1878-01, The

Indiana Progress, Indiana, Pennsylvania, July 25,

1878)

A June 14, 1893

Public Ledger article provides details on the initial manufacturing

and packaging of Hires Root Beer Extract, and the changes generated by

increasing demand for the product:

A Modest Beginning.

The beginning of this great business was a very modest one.

Mr. Hires commenced making the extract by boiling the roots,

barks, etc., in a five gallon kettle.

One young lady was able to bottle all the product without

overworking herself. The

first year 1000 packing boxes were made, and just 864 bottles were sold.

In five years the five gallon kettle gave way to a 20 gallon

copper kettle and the extract was made in barrel lots.

Three years later, the increase in business had been so wonderful

that a 100 gallon kettle was necessary and a 75 gallon percolator.

A percolator is a funnel shaped arrangement from which the

extract drips into receptacles.

Now, a large steam boiler, of more than 300 gallons capacity is

necessary; there is a large press of 80 tons pressure to the square

inch, which will press the life-giving properties out of three barrels

of roots at a time, and there are four 100 gallon percolators running

night and day. The extract

is made up in tanks of a capacity of 300 gallons each, and four of these

are going constantly. More

than 100 girls are employed in bottling, packing and casing the extract.

And there are 75 men and girls in the office and shipping room,

this number including a corps of experienced salesmen, who are

travelling the land from the Atlantic to the Pacific, and from the sunny

slopes of the Gulf to the ice-bound lakes of the North.

And all this accomplished in fifteen years!