1908

IT HAPPENED IN…1908

Prohibitionists stepped up their campaign.

Portions of New York, Ohio, and Colorado banned saloons,

while making or selling liquor became illegal in Tennessee.

The liquor faction argued prohibition would lead to fraud,

secret drinking, and drug abuse.

The Ford Model T, “a motor car for the

multitude,” was introduced October 1st.

William Howard Taft was elected President of the

U.S.

8,000 to 10,000 nickelodeons in the U.S. drew an

estimated 200,000 customers per day.

Newly introduced products included the electric

kitchen mixer and cellophane.

General Electric patented the electric iron and electric

toaster.

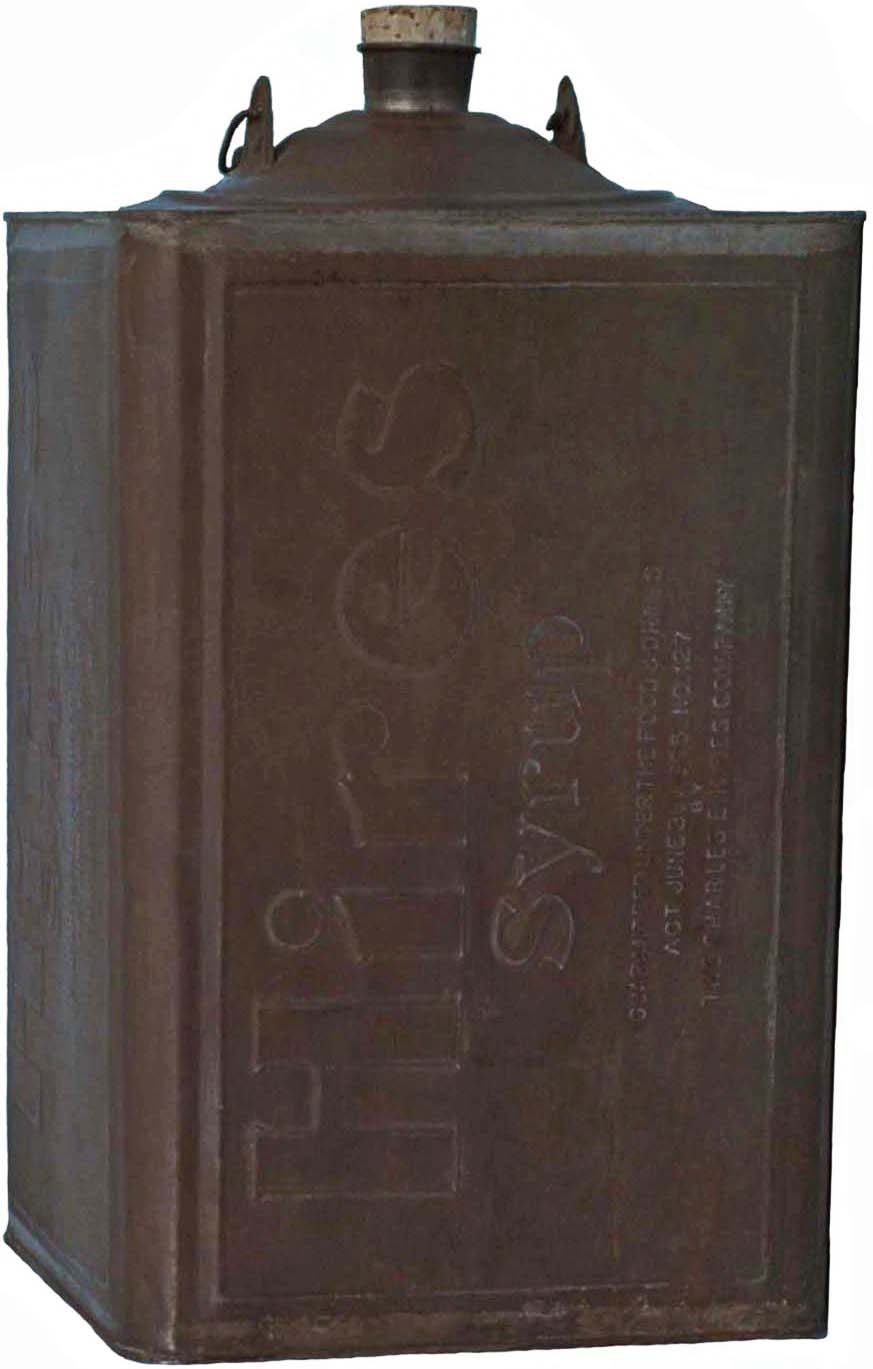

Five gallon Hires Fountain Syrup tins were packaged in wooden cases to prevent damage during shipping.

(Figure 1908-01, five gallon

Hires Fountain Syrup tin)

Hires added illustrations of the medals and awards the company won at fairs and expositions to their paper labels. This example was “BOTTLED AND DISTRIBUTED BY S. CANNON & CO., BURLINGTON, VERMONT.” The wording across the top reads “ITS USE IS A HEALTHY HABIT.”

(Figure 1908-02, crown top bottle with paper

label, 9.75” high)

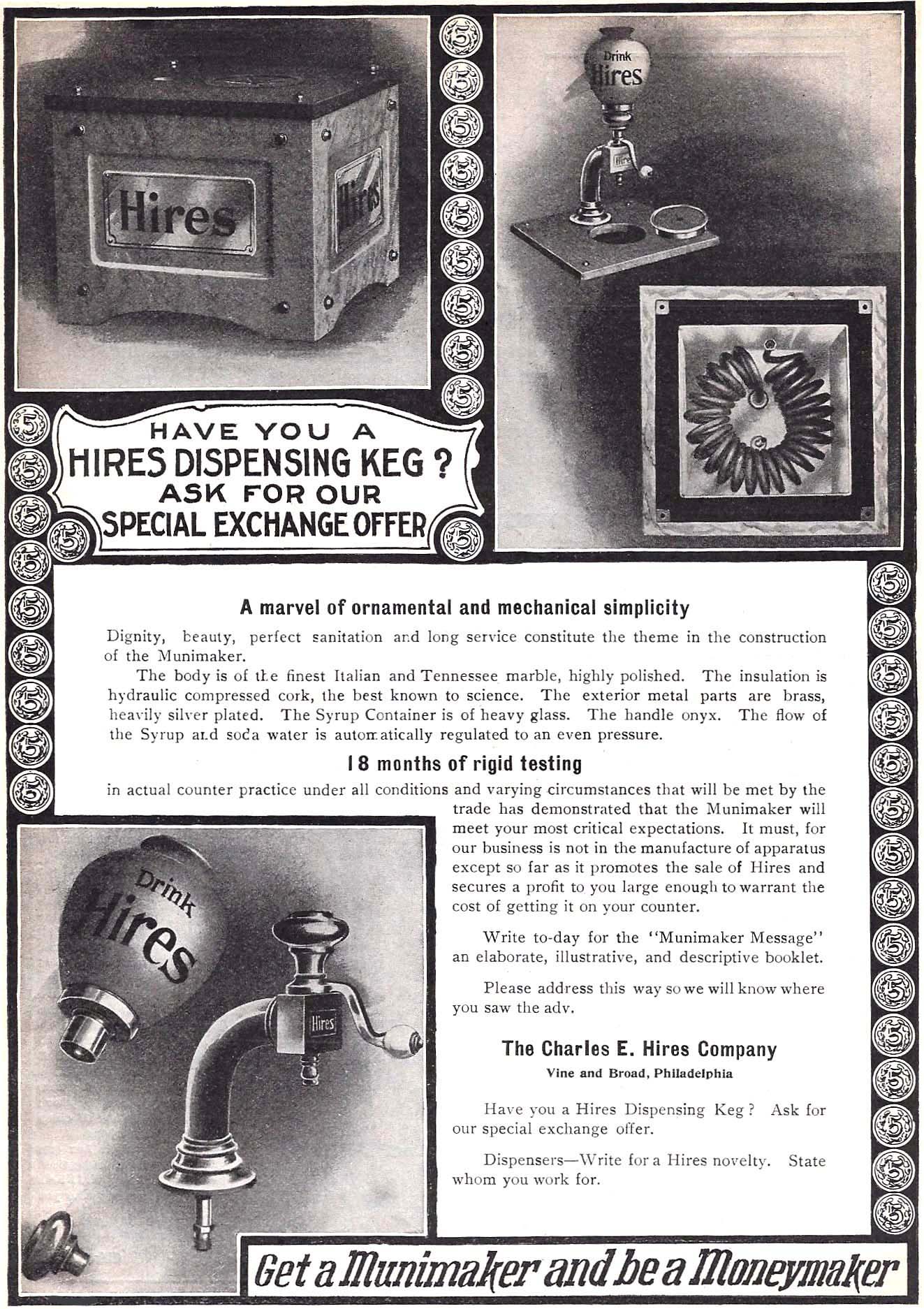

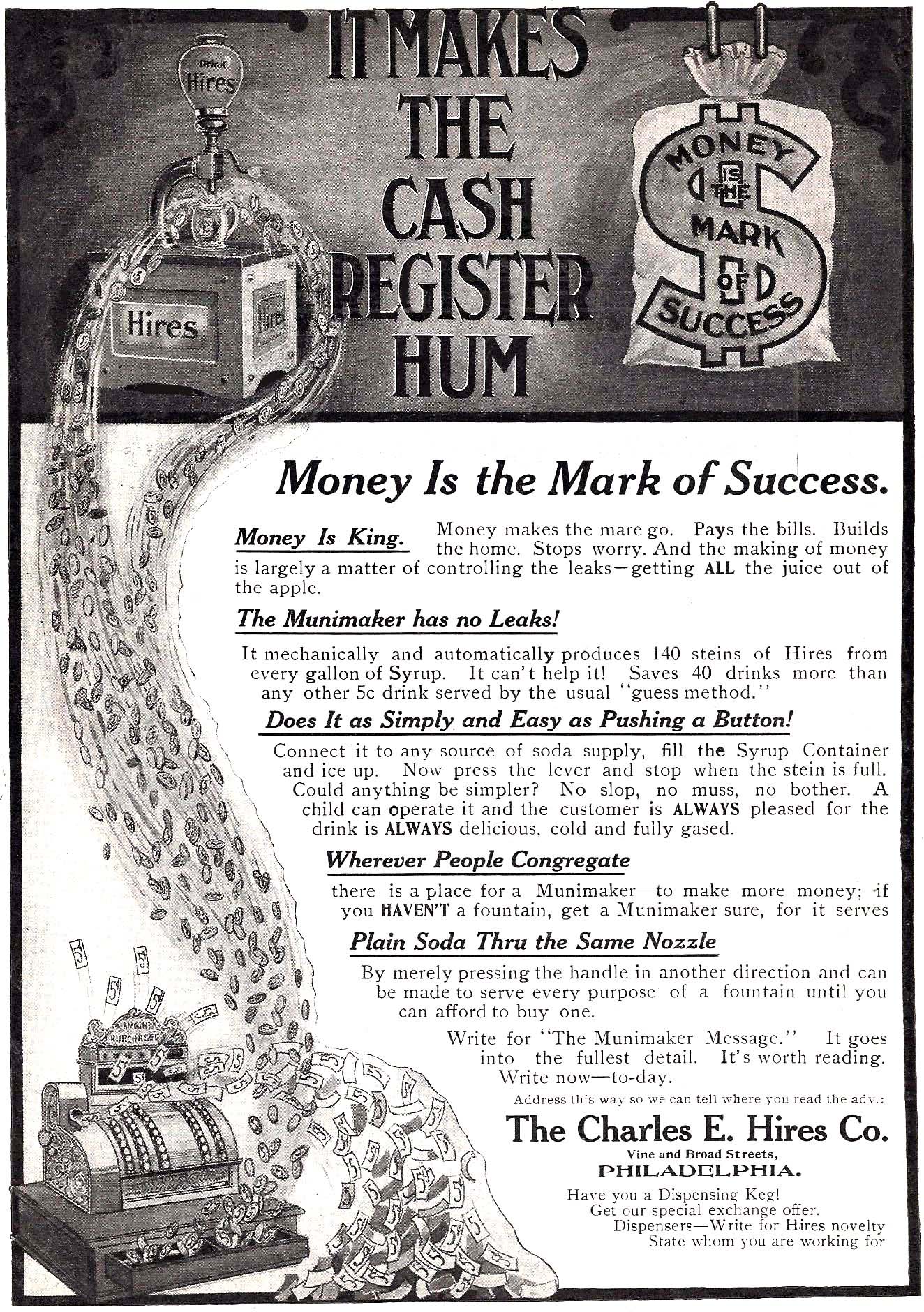

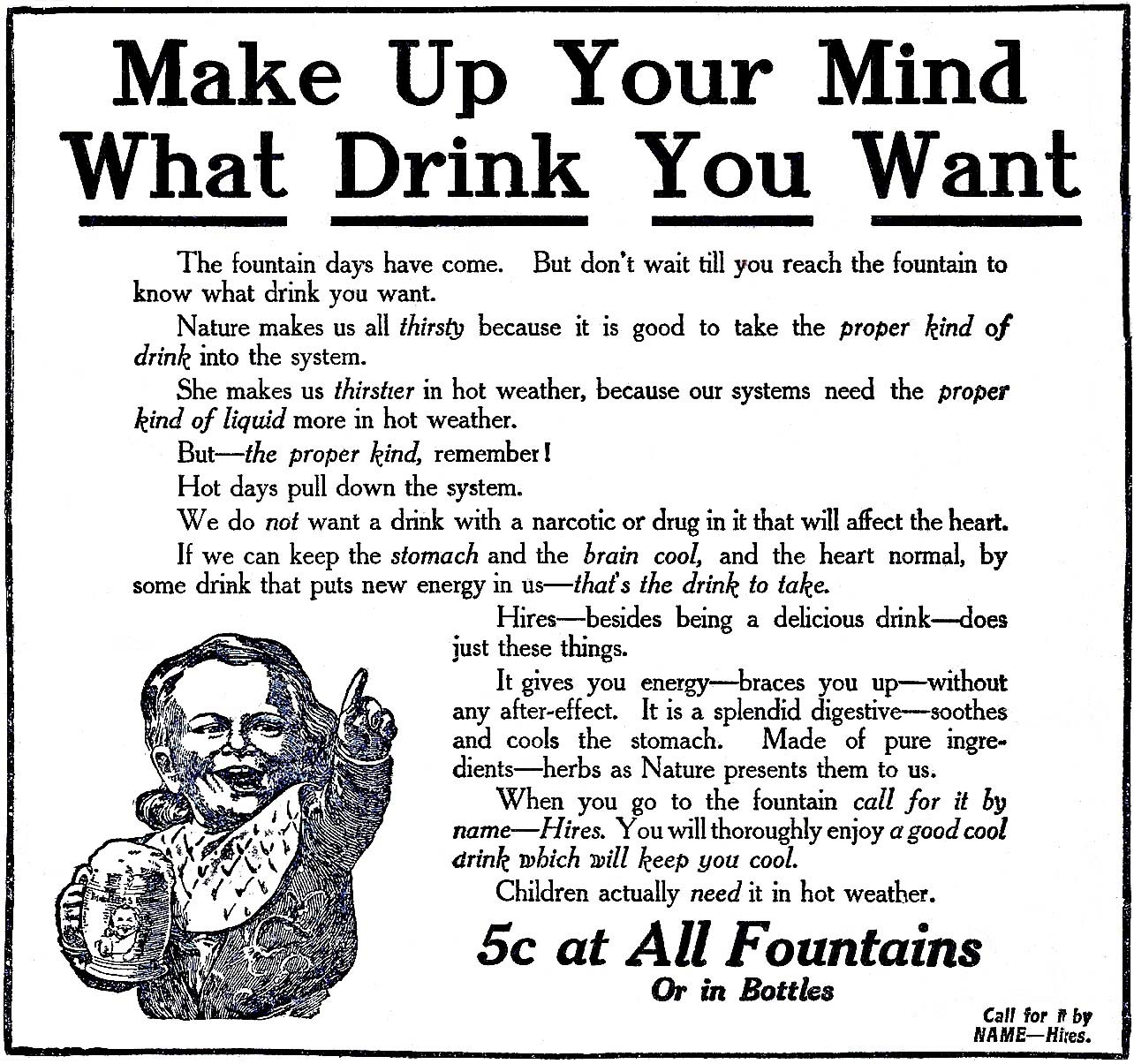

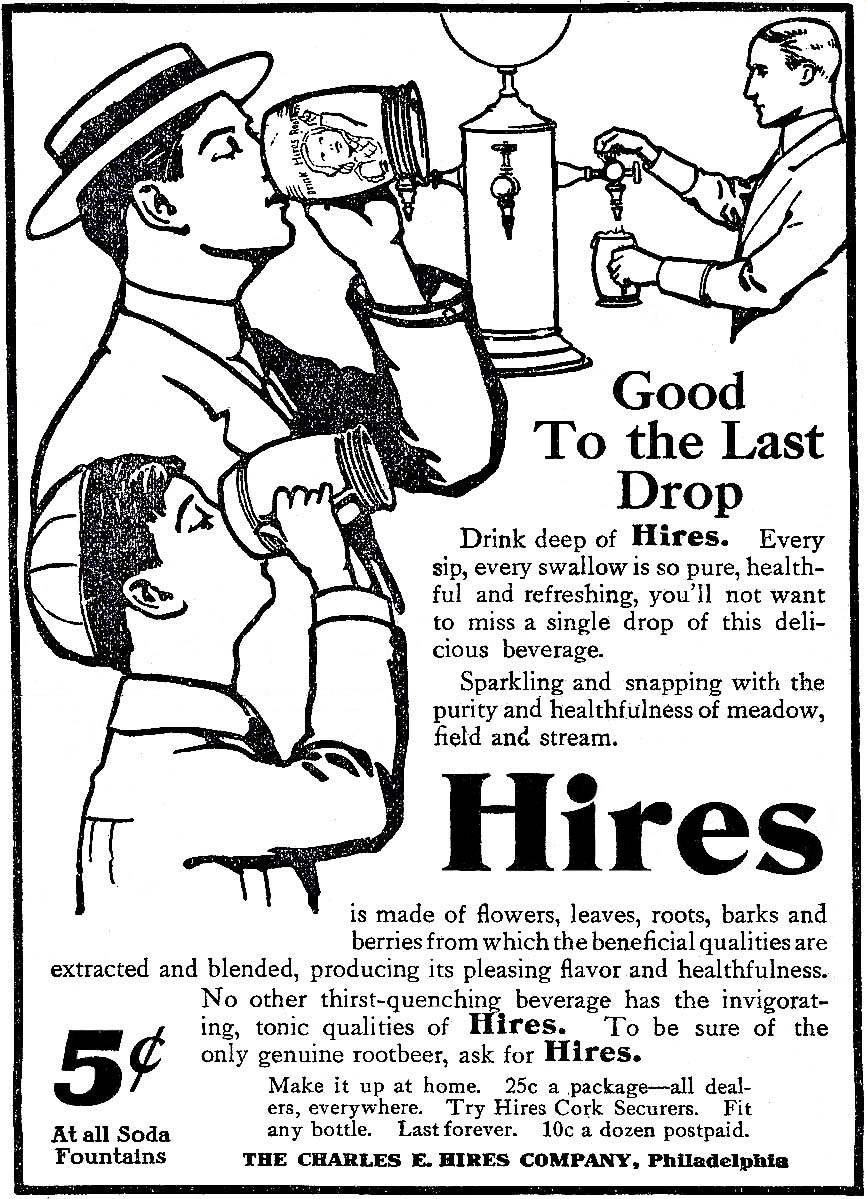

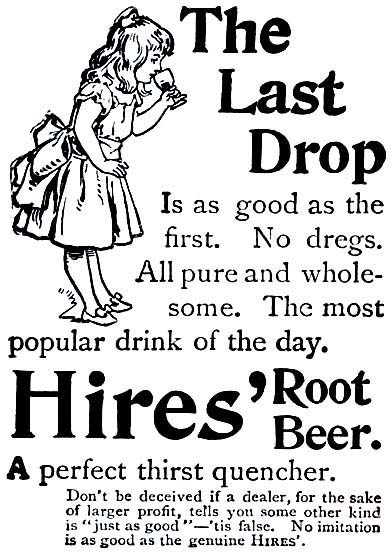

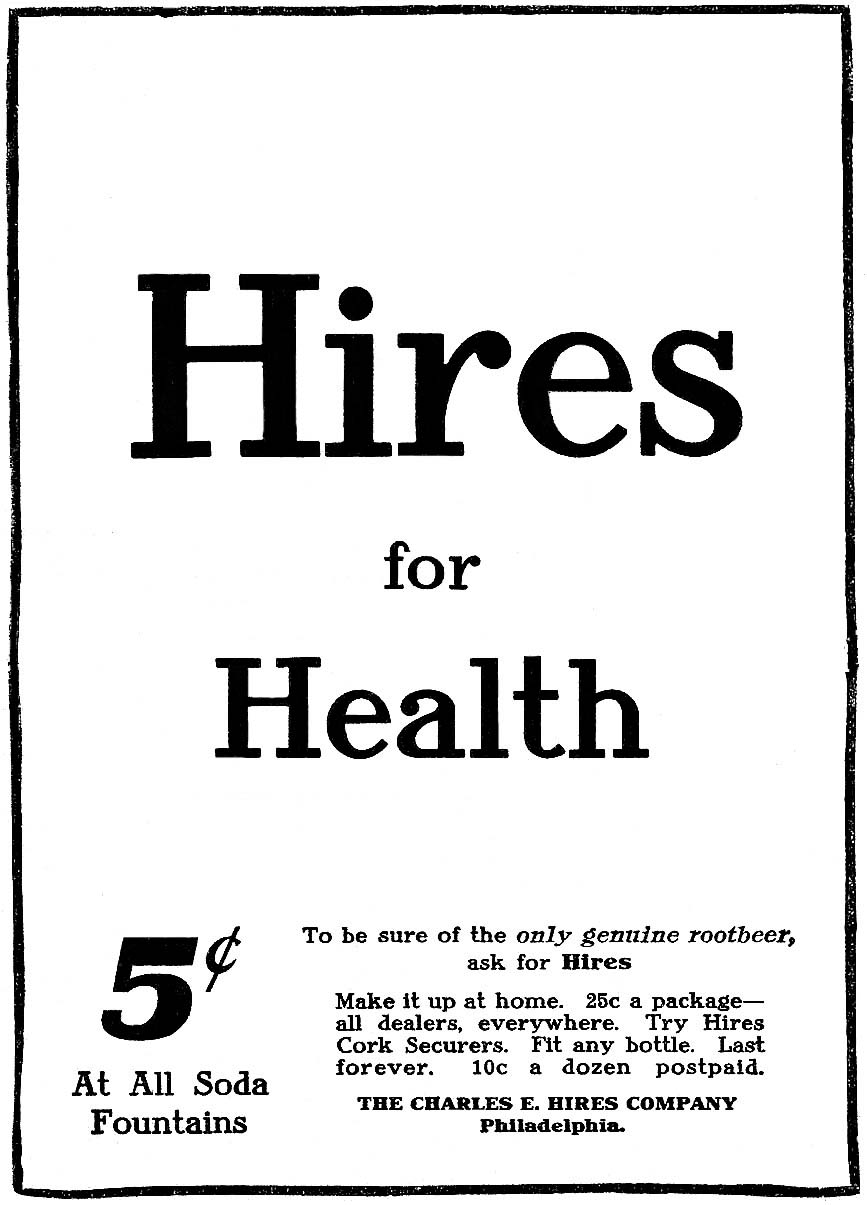

The following four newspaper advertisements ran in Philadelphia during 1908:

(Figure 1908-03, newspaper

advertisement)

(Figure 1908-04, newspaper

advertisement; also in the July 5, 1909 Kansas City [Missouri]

Star newspaper)

(Figure 1908-05, newspaper

advertisement)

This advertisement indicates Purock was “Delivered by our wagons to all parts of the city in sealed, sterilized bottles at 40¢ the case. From Druggists at 15¢ the gallon."

(Figure 1908-06, newspaper

advertisement)

This double-sided, die-cut, cardboard fan was produced for The College Ice Store in Dover, New Hampshire by F. A. Schneider, Lithographer, © 1908. In addition to Hires Root Beer, the store sold soda, candy, postcards, ice cream, and "the most Popular and Best Brands of Cigars and Cigarettes." The metal staples used to attach the handle have rusted with age.

(Figure 1908-07, die-cut,

cardboard fan, front)

(Figure 1908-07, die-cut,

cardboard fan, back)

(Figure 1908-07.5, newspaper

advertisement, June 8, 1908, 2.5" x 6.5")

Hires introduced another new product in 1908: “Try

Hires Cork Securers. Fit

any bottle. Last forever.

10¢ a dozen postpaid.”

(Figure 1908-08, newspaper advertisement,

July 14, 1908)

(Figure 1908-09, newspaper

advertisement)

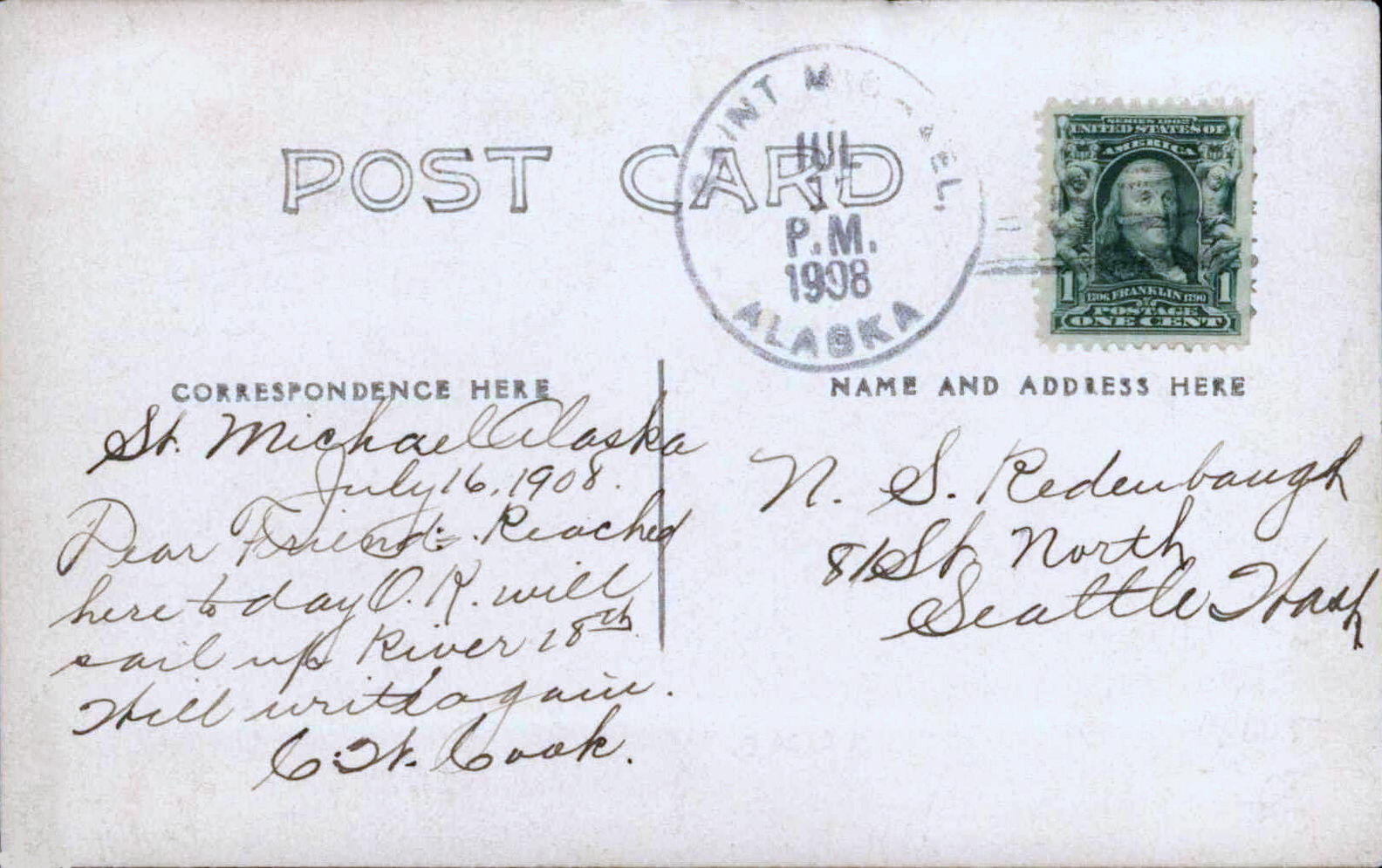

This real photo postcard pictures a bear drinking from a bottle.

The sign reads “I DRINK HIRE’S ROOT BEER AT TRAEGER AND WILLIAMS –

St. Michael, Alaska. St.

Michael was a trading post and the northernmost Russian settlement in

Alaska. Note the steamboat

in the background.

(Figure 1908-09.5, real photo

postcard, front)

(Figure 1908-09.5, real photo

postcard, back)

(Figure

1908-10, The

Bulletin, Philadelphia)

This easel-backed, cardboard display held 24 Hires' Cork Fasteners.

(Figure 1908-11, Hires’ Cork

Fasteners cardboard display, 15.0” x 13.0”)

(Figure 1908-11.5,

Philadelphia newspaper advertisement)

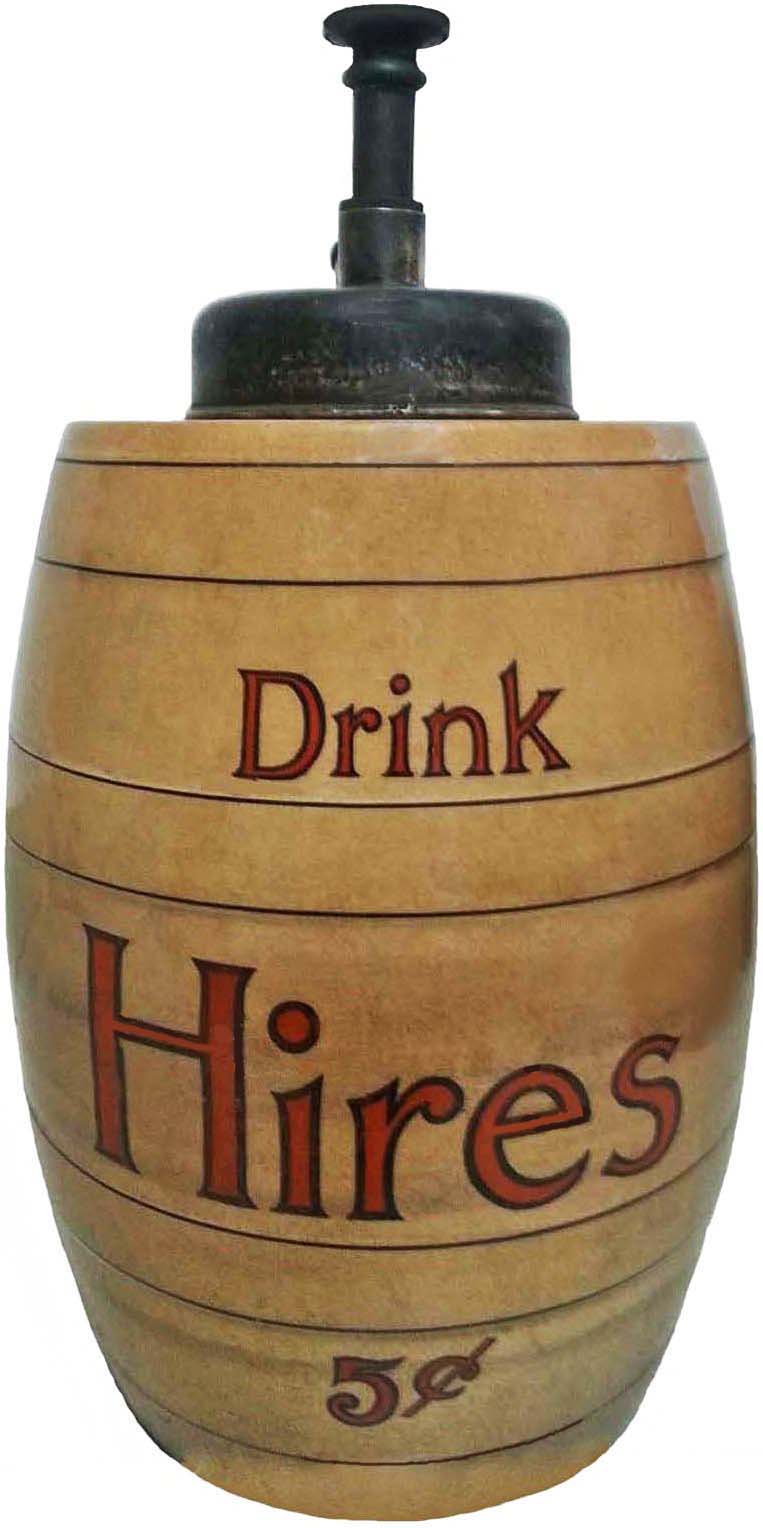

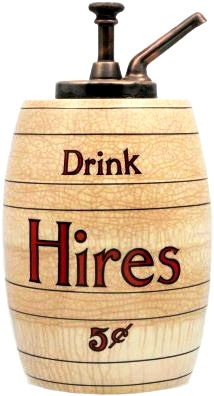

These stoneware syrup jars were manufactured by

Robert M. Green & Sons in Philadelphia, Pennsylvania.

Each has “Drink Hires 5¢” printed on both sides.

This was the first dispenser Hires utilized with a pump that had

a spigot at the top, rather than at the base.

This design change was made to eliminate problems with sugar in

the fountain syrup hardening over time, causing base-installed spigots

to clog. The illustrated

examples are 15.0" tall with 8.0" diameter bases. They have

slightly different style pumps.

(Figure 1908-12, stoneware

syrup jar with top pump spigot)

(Figure 1908-13, stoneware

syrup jar with top pump spigot)

This similarly-designed stoneware syrup jar featured the addition of a pedestal base.

(Figure 1908-13.5, stoneware

syrup jar with pedestal base and top pump spigot)

The base of this stoneware mug was stamped by the International Pottery Company, the Trenton, New Jersey firm that manufactured these mugs.

(Figure 1908-14, stoneware

mug, front, 4.0” tall, 3.0” base diameter)

(Figure 1908-14, stoneware

mug, back, 4.0” tall, 3.0” base diameter)

Charles E. Hires included these comments in “Some Advertising

Reminiscences 1869-1913:”

The transition period in our business came when the

bulk of the soft-drink trade was shifted from the cellar at home to the

soda fountain on the corner.

It brought with it a whole lot of new problems, among which was

our old friend substitution in a more subtle guise than ever.

How was the consumer going to know whether he was served with

Hires at the fountain or with something else?

When he bought a package of the household extract to take home,

he could read the proprietor’s name on the label, but there is no label

on a glass of root beer at a soda fountain.

Labeling glasses won’t solve it, because the clerk will keep the

bottle under the counter where the customer can’t see it.

Indeed, I hesitated a long time about putting a fountain syrup on

the market because of those facts, and because I felt that it was

necessary to the success of the drink that the syrup and water be mixed

more accurately than the average soda clerk is accustomed to handle

them.

The dispensing machine which we call the “Munimaker”

solved both problems at once.

It mixes the syrup and the soda water automatically and

instantly, in exactly the right proportions.

It identifies the resulting drink as Hires, for the dealer would

be a bold pirate indeed who would venture to serve any other kind of

root beer syrup through the machine.

He would be liable for violating the patent laws and his

contract, and we would catch him without delay because his purchases of

Hires syrup with us would stop while he was substituting, and one of our

men would be around to see if his machine was out of order.

Best of all, the Munimaker has opened up a great many new channels for the sale of the goods – in places which do not provide regular soda fountains. We have installed a great many in department stores, in Y.M.C.A. buildings, and even in saloons.

Here is another instance where Hires sent advertising

copy to a publication that printed it word for word.

This “article” ran in the November, 1908 issue of

The Druggists Circular trade

journal.

Hires’ Automatic “Munimaker.”

On pages 52 and 53 of this issue the Charles E. Hires

Company, Broad and Vine streets, Philadelphia, offers to soda water

dispensers the ‘munimaker,��� a new automatic dispensing apparatus for

Hires’ root beer.

Concerning this new dispenser and its development, the company says:

“The invention of the Hires automatic ‘munimaker’ has

back of it a very interesting history.

While working with the soda-fountain trade we were continually

confronted with two conditions which we knew should not exist.

First, that Hires’ root beer was not being rightly dispensed;

second, that no soda fountain drink was being dispensed with the right

profit.

“The second condition was due to the first. Under the prevailing method of dispensing at the soda fountain, the dispenser was compelled to guess the amount of syrup necessary to be used for each drink. Guess work always means waste, as it is impossible for a dispenser in his haste to gauge exactly with the eye – in guessing he invariably overdrew the amount of syrup necessary for the drink. This comes from the fact that a customer is less apt to complain if the drink is too heavy than if it is too light. Therefore the dispenser does nothing more than anyone else would do. He moves along the lines of least resistance.

"We gained nothing through the dispenser’s drawing

too much syrup because it tended to make the drink unsatisfactory, and

the dispenser gained nothing because he lost a fraction of an ounce of

syrup with each drink, which properly belonged to his profits.

“Anyone owning a soda fountain, who is interested in these things, can learn a great deal by a little investigation and this investigation can apply to himself as well as to those under him. He has but to ascertain by actual count the number of drinks he gets from each gallon of syrup. This can be done by measuring the syrup in the morning; keeping track of the number of drinks of each flavor served during the day, and then measuring the syrup at night. This is about what he will find – that a gallon of syrup requiring one ounce to the glass will produce about 100 drinks and the syrup requiring two ounces to the glass will produce 51 or 52 drinks. As a matter of fact, he should get 128 drinks from each gallon of one-ounce-to-the-glass syrup and 64 drinks from a two-ounce-to-the-glass syrup. This loss is so gradual that is scarcely perceptible in the individual drink.

“We believed that if we could make an apparatus that

would serve Hires right and give the dispenser a profit which he was

entitled to, we would find a ready market for it.

This was very readily proven in the distribution of the Hires

dispensing keg and the fact that the dispenser was willing to pay a fair

price was promptly shown, for we started to market this apparatus at

$25. Finding we could not

make it at that figure we raised the price to $50, and then to $75.

Each time we raised the price we made the apparatus better, and

each time we raised the price dispensers bought more of them until by

the time we discontinued its distribution we had the output up to more

than 6,000.

“During all this time we were carrying on active

experiments and in this process we finally discovered that the faults of

the keg were insurmountable.

We also found that we could not patent the keg for, though it was

original with us, it contained no novel feature.

Wood is a very difficult article to handle mechanically.

We then tried to eliminate the wood by experimenting with a metal

keg for one whole year, in our place of business, putting it through the

same trial it would have to undergo at the soda fountain.

It failed to make good for several reasons.

This discovery practically eliminated the keg, and necessitated

our trying something different altogether.

In this latest move we determined to be original as well as

novel, so that would not only patent the design but the mechanism, and,

thus came about the Hires automatic ‘munimaker.’

We put this through eighteen months of counter practice before we

announced it to the trade.

To go into details of how it reached its present equipment would mean

simply a recountal of a number of petty obstacles, some of which were

almost large enough to throw the apparatus out of service.

The vagaries of gas pressure, for instance, are something little

known to the average man.

Suffice it to say that the final outcome is an apparatus which we

believe to be perfect in every respect.

We shall of course go on making alterations here and there in the

direction of improvements but it is the one apparatus which shall

hereafter be identified with Hires as an automatic dispenser.

It has all the points essential to make this so: mechanism that

will work and materials that will last.

It is an apparatus wholly in harmony with the finest store

fixtures. Its simplicity of

operation cannot fail to appeal to everyone.

It will find its place on every soda fountain because it helps

the dispenser to produce 140 drinks to the gallon of Hires as against

100 when dispensed by the usual guess method.

That means 40 drinks more than the dispenser will make from any

other five-cent syrup, or $2.

Two dollars to the gallon means $100 to the barrel.

It is not difficult to see that the dispenser is thus enormously

the gainer in dollars and cents.

“We have made it necessary for us to sell forty

drinks more to each gallon of syrup than the dispenser would get in the

usual guess method. This is

an evidence of our confidence in the apparatus and we are willing to

sell forty drinks more to the gallon for him, in order to get a better

flavor for we know that once a dispenser gets Hires just as he wants it,

he will want more Hires syrup and there will be more people who will

drink Hires. We send him

2,000 more customers and he gets 2,000 more drinks to the single barrel

of syrup.

“We do not doubt for a moment that the ‘munimaker’

will find a tremendous success because it means a tremendous profit to

every man who has it on his counter.”

This Munimaker advertisement ran on facing pages in

The Western Druggist

magazine.

(Figure

1908-15, The

Western Druggist, November 1908, page 8)

(Figure

1908-15, The

Western Druggist, November 1908, page 9)

This single page advertisement was placed in

The Western Druggist the

following month.

(Figure

1908-16, The

Western Druggist, December 1908)

The front cover of the December, 1908 issue of

The Soda Fountain monthly

journal pictured a storekeeper using a Munimaker to fill a Hires stein.

(Figure

1908-17, The

Soda Fountain, front cover, December 1908)

%205¢%20(on%20both%20sides)%20stoneware%20syrup%20jar%20with%20pedestal%20base%20and%20top%20spigot.jpg)